The CPI indicator is your tool in the improvement work

CPI is a module in the MUR System

Machine-Utilization in Real time

Production and run / stop time registration

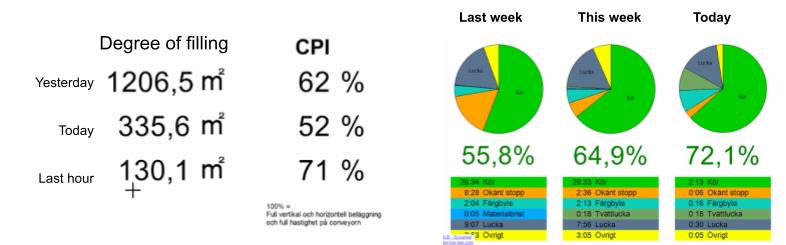

The CPI provides summary information of:

Degree of filling vertical - Degree of filling length

Conveyor speed - Construction time

Degree of filling vertically: A measuring frame detects how much has been hung vertically.

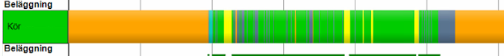

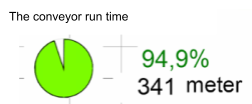

Degree of filling length: How many gaps are there in the hanging.

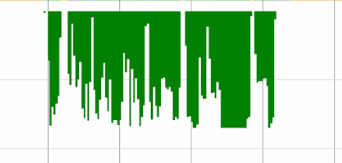

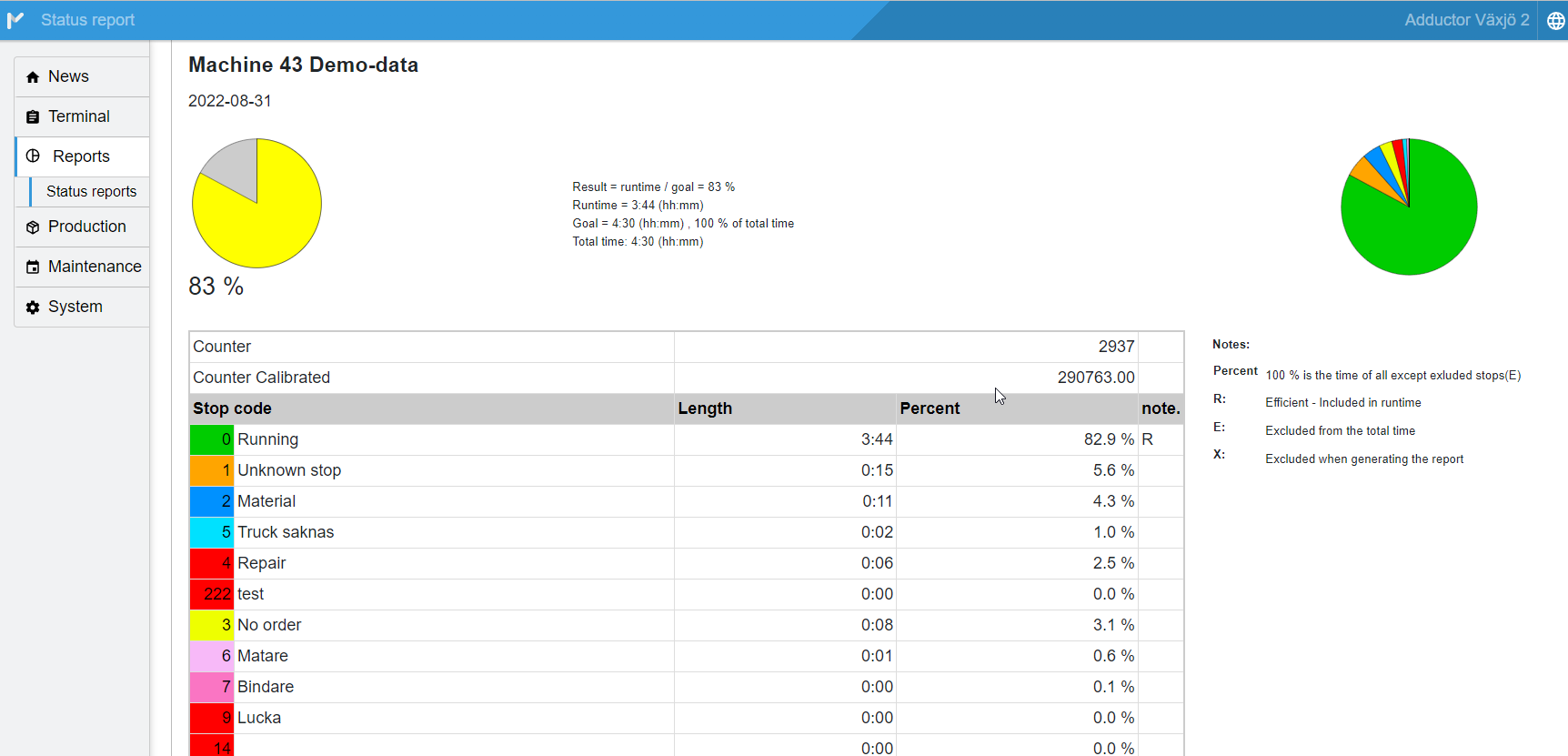

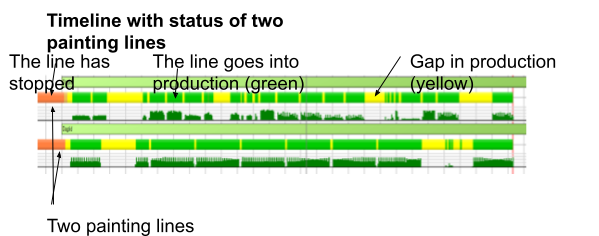

The gaps are shown in the time graph, highlighted in yellow. The pie chart shows the degree of filling during the shift/day

Conveyor speed: The deviation from the intended speed.

Installation time: How much of the estimated production time is used.

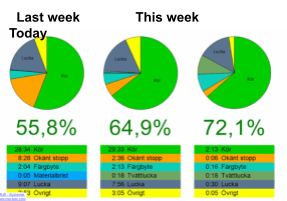

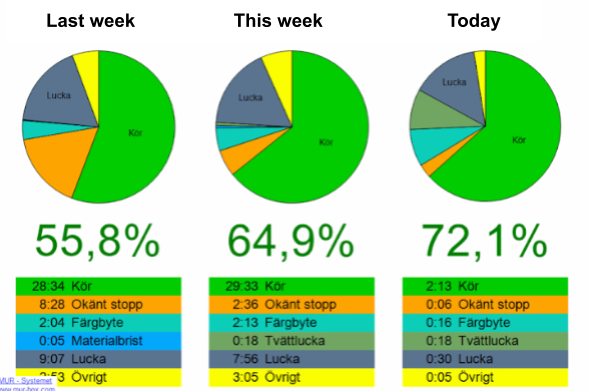

Total utilization rate today 72.1%

All stop reasons are reported for each period.

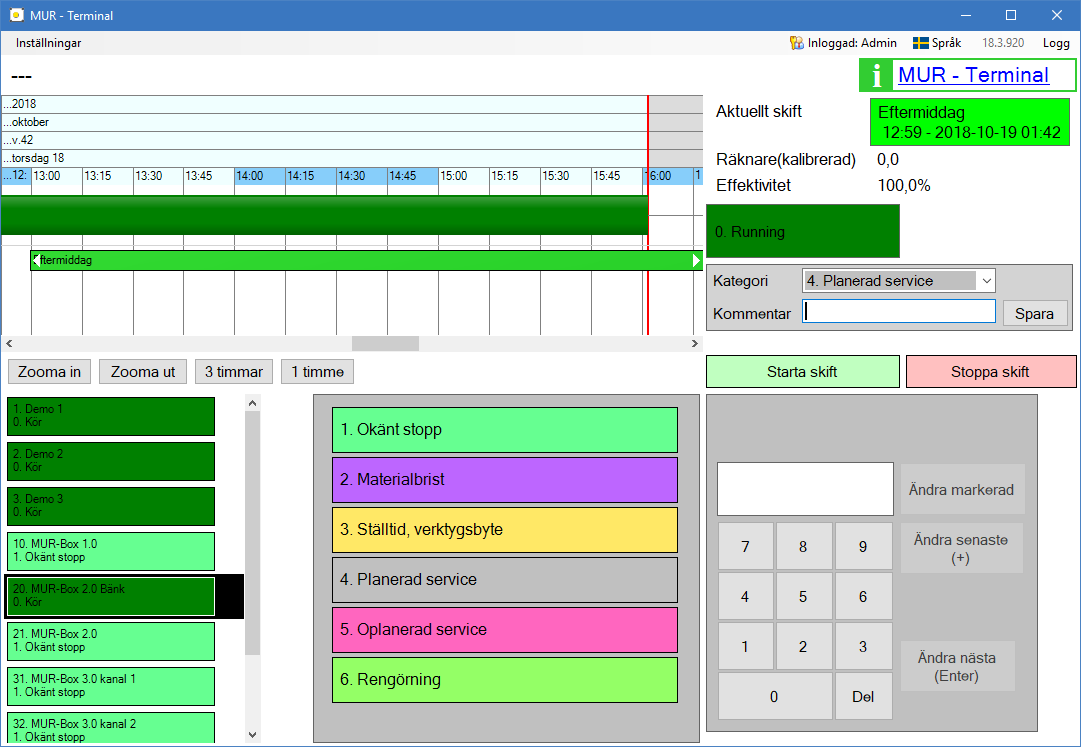

Below is an example of the CPI/MUR Information screen

During installation, you get help with the first one information screen, with information which is important to you.

The installation package includes a course in making an information screen. Making an info screen is pretty much like that use a word processing program.

Installation of the CPI system - 1/4

CPI is a module in the MUR System.

The installation starts with installing a MUR-Box.

It is the MUR-Box that takes in signals from the measuring frame and pulses from the conveyor (approx. 1 cm/pulse).

Several keyboards can be connected to the MUR-Box, from where the operator can easily specify the stop reason.

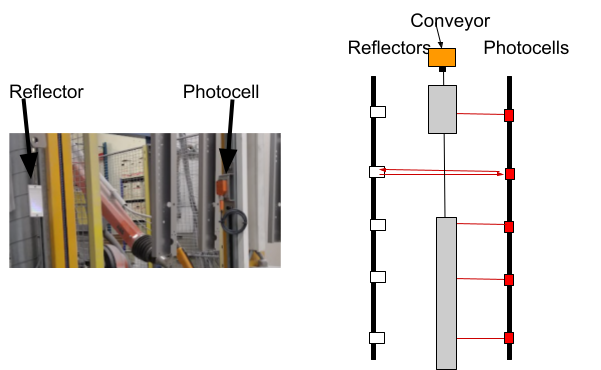

Measuring frame - 2/4

4-5 photocells, whose signals go to the MUR-Box.

Stop reasons - Reports 3/4

All stops on the line are registered automatically.

The operator can directly enter the reason for the stop at the MUR-Box's keyboard or at a terminal. The stop reasons can also be changed afterwards.

At the same time, the operator can provide additional comments on the stops. These comments are included in the reports generated in the MUR System.

The MUR system is connected to the company's LAN network, which means that anyone with the right authorization can access the data that CPI/MUR generates. For example, everyone can have their own info screen on their computer that provides the data that is particularly interesting to the user.

The CPI/MUR programs are installed free of charge on an unlimited number of computers and an unlimited number of users. The same for the use of the Info screen.

CPI/MUR System 4/4

The CPI/MUR system can be installed in your LAN network to give anyone with authorization access to generated data and reports. Can also be run as a stand alone. Useful for temporary installations.

CPI/MUR is an independent system, i.e. not dependent on other programs or measurement systems. This means that troubleshooting does not need to involve more than one supplier.

CPI/MUR is a scalable system with which all programs have the opportunity to communicate, for example to retrieve data from CPI/MUR or for CPI/MUR to deliver data to other systems.

Short-term rent a complete CPI system

A CPI system with MUR-Box, PC and measuring frame.

You get it installed and a walkthrough of CPI. We provide you with an information program for the information screen, adapted to your needs. Report generator that you can easily print out a report for the desired period on a daily basis.

When we have done work with you, you have full control of the CPI system. Everyone in the company can have access to CPI, to the extent that the logged in person has been authorized to do so.

Meyer&Hjort has used CPI during their work at Nimoverken

Roger Fröjdh

Roger's entrepreneurial heart from Småland means that he often sees new and unexpected opportunities in businesses that have run into trouble.

He has a solid background in the surface treatment industry and below his management, he pushed up a Lego painting company to become Sweden's most profitable.

Roger has also been a partner in a chemical company.

Roger Fröjdh's experiences with CPI:

The CPI Report is used as a basis for decision-making as it is a conclusion.

The info screen is clear and easy to understand. It shows the department/facility information in real time.

The staff can link measures in real time where the effect is visible directly on the screen.

With the help of the information on the screen, you make the right decision where the effect is disturbed

Facts about Meyer&Hjort

"Surface treatment department for rent"

Many companies today often do not have the resources to have their own surface treatment department.

"Surface treatment department for rent" means that you can have one but only pay for the time you have agreed. At the same time, you easily get the necessary competence that a completely separate department would bring. From painting specs to complete systems.

With our competence and experience, we take responsibility for the company's overall surface treatment, selection of subcontractors, in support of market and construction as well as production in our own facility.

Ytab uses the MUR-System for measurements on manual work

YTAB started with measurements on the paint line and then came the idea of measuring on manual work

Why did you want to measure on the paint boxes?

We wanted better information on the flow in the boxes. We needed to know effective time for preparation / painting / drying times in the box to be able to control flow and resources and ultimately increase capacity without working faster, only smarter.

What new information did the measurements provide with the MUR-Box?

It provided important information about potential capacity, what improvement measures we needed to work on.

What measures were taken after seeing the measurement results after the first measurement period?

We have completely changed the flow of work outside the boxes for the preparation. This work was visualized and we increased efficiency by over 20% compared to before.

How do the staff take part of the measurements and what response they give via the MUR-System.

The staff looks at the MUR Info screen, in real time, the number of minutes the box has been stationary. We also show daily measurements and monthly measurements. This has increased the commitment among all staff who work inside and outside the boxes.

About YTAB

Specialists in surface treatment with a strong focus on plastic and composite.

Varnishing plants in Sweden and Hungary.

Total number of employees: about 120.

CW Lundberg Industri measures two painting lines as well as a number of CNC machines

Production technician Lars-Åke Engström at one of the coating lines.

- The staff has been careful to write comments then Once a week / week go through with production technology / process managers what have been disruptions in production, says Lars-Åke.

What parameters on the paint lines were interesting when you started measuring?

What we wanted to see was how we use the paint line. With the MUR-Box we were able to start measuring our shut-off hatches, changing colour hatches and gaps between the suspension yoke. In this way we could see how much detail passes through the paint box, and when we started to use the fill rate we got a better look at the utilization rate. We get the fill rate by reading the signal from the light beam.

How are the parameters used?

What we use the parameters for is to see the utilization of the line and the fill rate through the lacquer boxes.

Stop times are an important parameter to work away from.

The comments are important to address the disruptions in production. The comments enter the operators into the MUR System's terminal program and become directly accessible.

In this way we can work away the disturbances in production.

CW Lundberg Industri

In what way have the measurements affected the production?

For our part, we can see how things went the day before and evaluate this, also use it in planning how the optimization of the products should be run.

How has the MUR-System affected the commitment on the paint line?

For our part, the importance of optimizing the line has increased, we are running more efficiently today than earlier.

The staff has become sure to write comments and then go through the production technique / process manager once a week / week what have been disruptions in production.

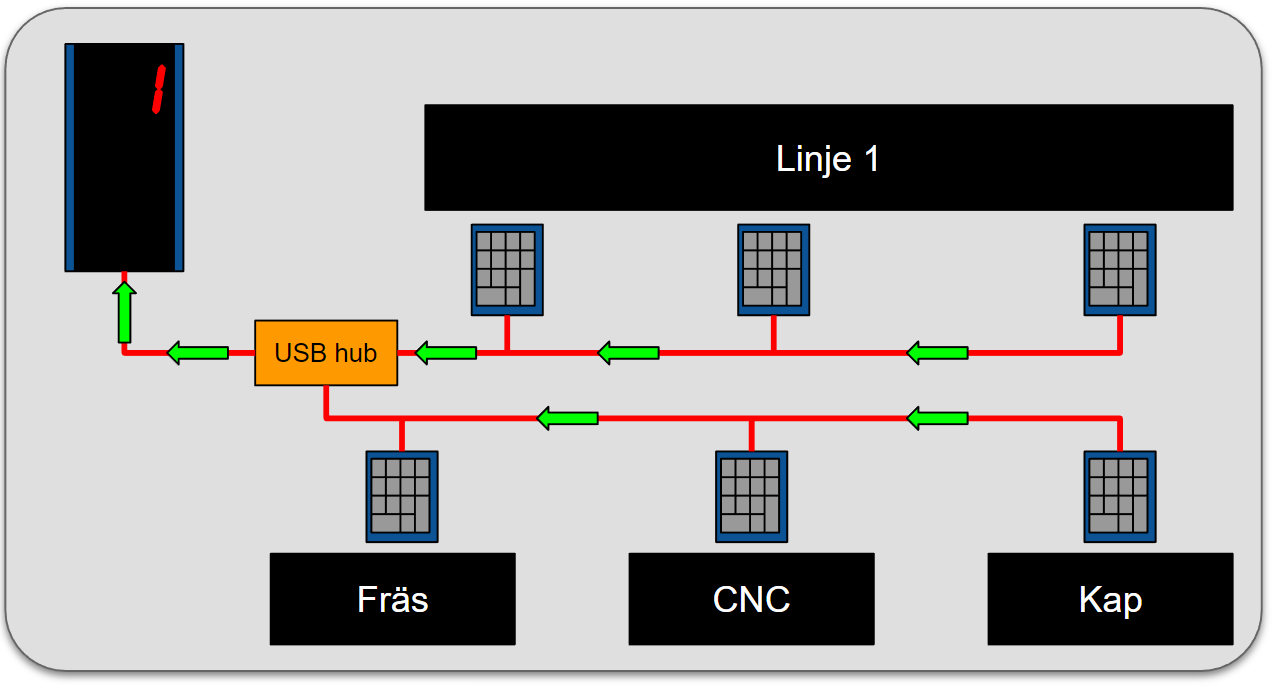

CWL also measures on five CNC machines

One MUR-Box can measure on several machines, up to 12 pcs.

The image below is not from CWL.

Indicates that each machine can have one or more individual keyboards.

About CW Lundberg Industri AB:

Expert on roof solution.

When designing your roof with graceful, environmentally friendly products from CW Lundberg, you can customize the color to the wishes and appearance that lifts the entire property.

You choose color according to a color map at no extra cost is obvious to CW Lundberg.

Through selected materials, professional production and surface treatment, you always get products that can withstand harsh environments, reduce stress on the roof and person in cases and enable an ergonomic and safe working environment.

Nimoverken uses CPI on its painting line

How is the CPI used by the staff on the line?

Positive reactions.

Direct information on how things are going.

Previously, you could only guess how it would go.

The information gives the staff extra energy for work.

How are machine comments used by operators?

At each color change, comments are added.

In case of special errors, e.g. during pick-up, during inspection, when material is missing.

How has the suspension been affected since you started with CPI?

Very visual with CPI, on the Info screen or in reports.

Gives thoughts that "We have to work on this".

The graph on the hanging has affected the work by preparing the hanging differently.

What reports are used in the daily briefings?

The standard report that provides information about the day's work, e.g. stop reasons, degree of utilization and gaps in the line.

The energy reports, the graphs from the CPI, what kind of "new eyes" have they given and how is the information used?

We see in the graph how changes in production affect electricity consumption.

The graph provides a direct visualization of consumption.

Streamlining - less shifts.

Can see immediately that energy consumption has decreased.

In what ways has the CPI affected production?

The working methods.

Changes in shifts.

More people in the company have gained insight into the production in a clear way.

CPI provides participation in production.

About Nimo

NIMO is today the world's largest drying cabinet manufacturer with just over 100 committed employees, of course we still have all our manufacturing in Sweden

Our goal is that our products should make it easier for both you and the environment every day.